We use Hildebrand Solubility Parameters to characterize the solute in your cleaning application and then match it with the appropriate solvent.

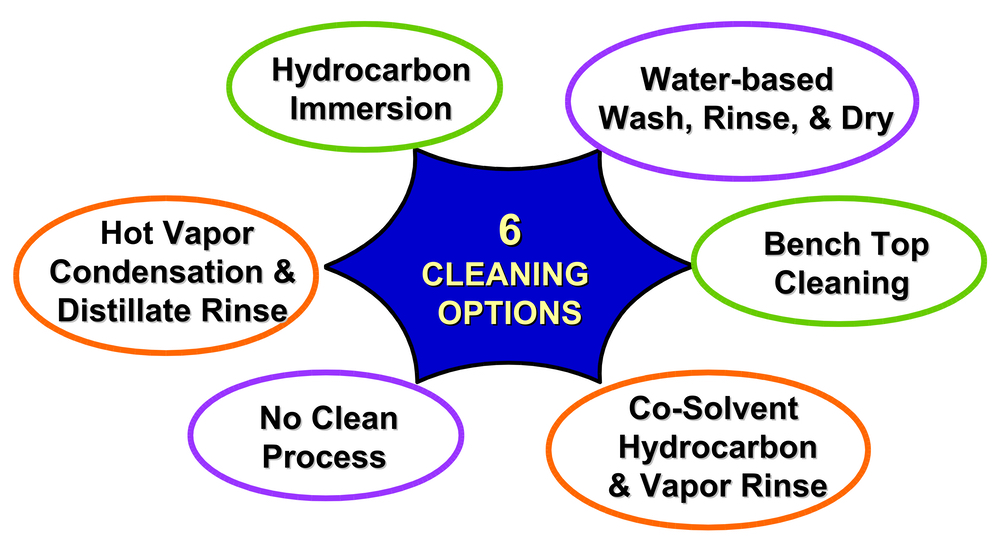

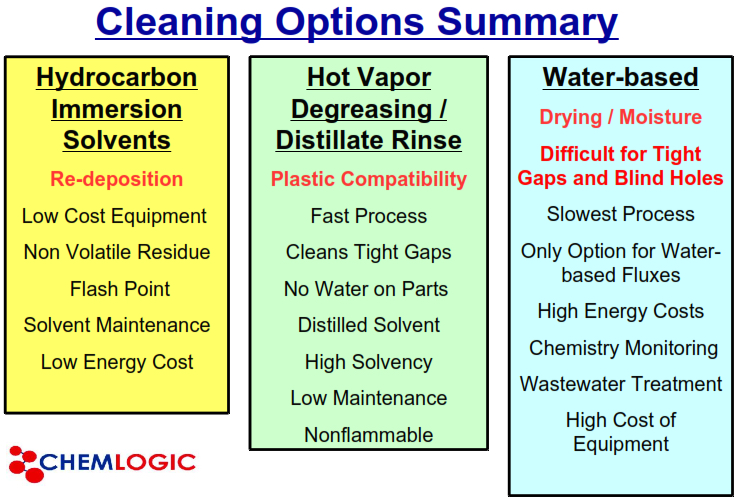

If a vapor degreasing process cannot remove the contamination, then we will utilize blended hydrocarbons or water-based chemistry (alkaline or mildly acidic) to cut through the contaminants.

When parts are submersed into one, two, or three tanks of a solvent blend, this is called Immersion Cleaning. It may involve the dunking of a basket of parts in a tank, followed by a cleaner tank of the same solvent.

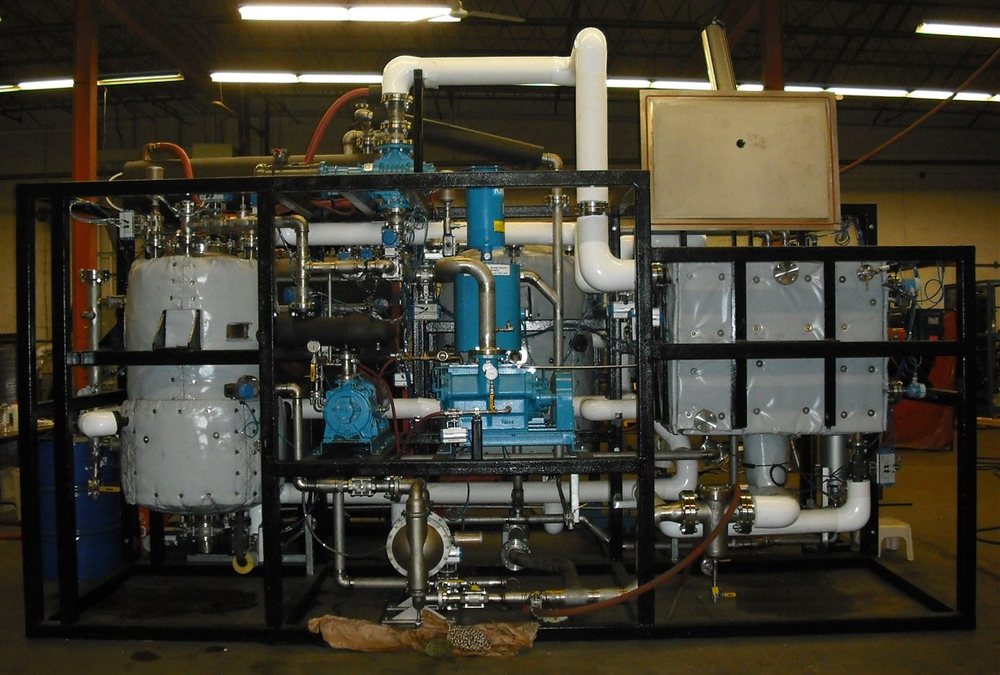

The benefits of a Vacuum Degreasing process are the minimization of solvent used (it is recycled by distillation), the almost zero solvent emissions, and the ability of the system to remove, by vacuum, contaminants from all of the nooks and crannies of the parts being cleaned.

Water is a fantastic solvent and we can fine tune the water solution with additives to be alkaline (high pH) or acidic (low pH), and add surfactants to make it easy to clean in tight spaces.